Which Top 5 High-Performance Crypto Gaming Tokens Should You Invest in 2024?

April 30, 2024

Navigating Change: Metaverse Game Development Post-Bitcoin Halving

April 30, 2024As we have now stepped into 2024, manufacturing businesses strive for a better approach to scale up their profits. Blockchain, in this case, has emerged as a revolutionary technology that has the potential to transform businesses, including manufacturing. There is no denying the fact that the supply chain is the foundation of the manufacturing business. The Blockchain’s distributed ledger structure and block-based approach increase visibility across the supply chain and improve the efficiency necessary for its sustainability. Blockchain in manufacturing strengthens the supply chain model, focusing on the areas of improvement to avoid financial loss or reputation harm. The improved supplier order accuracy, product quality, and track-and-traceability are some of the perks of using the supply chain blockchain development, enabling businesses to meet their delivery dates on time and sell more without compromising an inch of quality.

In this blog, we will discuss the growing importance of blockchain in manufacturing industries and its potential to address the shortcomings of industries.

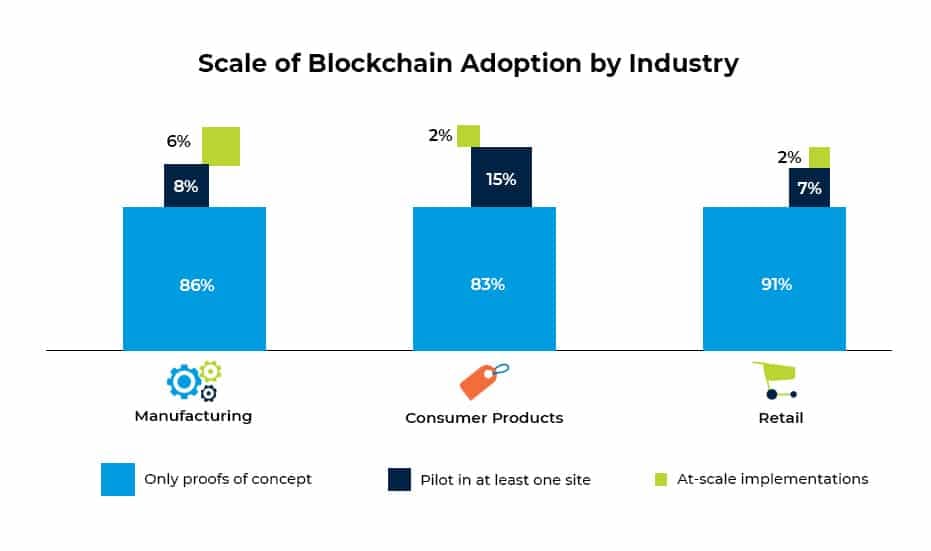

The Scale of Blockchain Adoption in Manufacturing

Capgemini’s research shows that the manufacturing sector has the most organizations that are actively using blockchain (most are at an early stage) than the other two industries, consumer products, and retail. (see the below fig.). This indicates a growing recognition of the potential benefits offered by blockchain in manufacturing sector such as enhancing operational efficiency, transparency, and trust across the supply chain.

Leveraging Blockchain in Manufacturing

- Product recalls could be averted with blockchain-enabled tracking and traceability

Did you know typical product recalls cost $8M and many could be prevented with blockchain-enabled track-and-traceability? Blockchain’s distributed ledger structure keeps track of all transactions in real time and secures them from modifications. This trait makes blockchain in manufacturing an ideal choice for the industry that needs thorough audits and follows strict compliance rules.

- Combining IoT and blockchain in supply chains boosts product authenticity, and transparency and reduces counterfeiting.

Manufacturers competing in highly regulated industries such as Consumer Packaged Goods (CPG), Aerospace & Defense, and pharma are also exploring how blockchain can provide them a distinct advantage in today’s market. Manufacturers in these sectors focus on IoT and blockchain integration as these technologies provide real-time data, such as shipping container conditions, storage, shipment location history, temperature, and product condition. Any change in the shipment’s temperature (measured by a sensor) sends alerts regarding whether the perishable meat or produce meets contract requirements or not. It prevents problems like poor product quality and rejected shipments upon arrival.

- Cost savings, track & traceability, and transparency are the top three drivers behind manufacturer’s blockchain investments

Capgemini’s research illustrates the manufacturer’s priorities to invest in blockchain. The research shows cost savings, track and traceability, and transparency are the top three drivers across manufacturing organizations that drive their blockchain investment. As manufacturers increasingly prioritize efficiency and reliability, blockchain emerges as a pivotal tool to meet these objectives, offering tangible benefits and long-term value in an evolving market landscape.

- Supplier contracts management is the most popular blockchain use case for manufacturing organizations

Estimates show that inefficient supplier procurement, management, and freight administration costs businesses in the UK alone $2 billion annually. Large manufacturing organizations deal with multiple suppliers. Traditional contract management involves a lengthy process of negotiation, authoring, execution, payment, and renewal that needs to be done across multiple departments within the organization, hence making the process cumbersome.

Smart contracts on blockchain can resolve the challenges of the traditional contract by programming them into a digital contract that executes automatically when certain events happen. With blockchain in manufacturing, businesses can establish a distributed peer-to-peer network, enabling suppliers to interact with each other without the need for an intermediary, in a verifiable manner. It offers a myriad of benefits, including improved execution speed, faster dispute resolution, and a faster payment mechanism for the suppliers involved.

Conclusion

The supply chain of manufacturing organizations has become increasingly complex over the years. Tracking & traceability, transparency, and security have always been the barriers to a more efficient supply chain network. However, blockchain in manufacturing can resolve these challenges and unlock a new level of efficiency. Although there is a long way to go for mainstream blockchain adoption, the implementation of this technology can be seen on a small scale. Organizations seeking a better approach or method to drive their business value can rely on supply chain blockchain development. Trust the expertise of a reputed company, Antier for blockchain supply chain solutions for manufacturing company’s growth. We have worked with global clientele from the manufacturing industry and provided them a comprehensive support to achieve full transparency and efficiency throughout their supply chains. Share your project requirements with our team and let our team support your business vision.